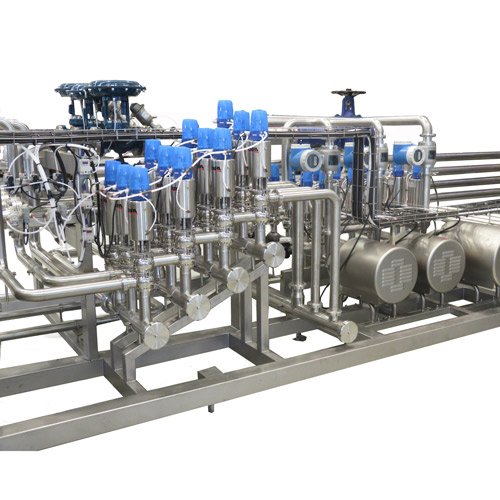

INOXPA CIP Skid Automatic Static System

Description

Specification

Description

The CIP Skid consists of a glass attached by a clamp for easy inspection of product levels and processes in various industries. INOXPA designed a range of static frame-mounted CIP systems to help to clean plants, eliminate impurities, and reduce bacteria levels.

Specification

Specification

- There are 3 parts to this CIP equipment range:

- A base frame with different components

- Tanks for water and chemical products

- Pipes and connections between the tanks and the base frame

- Customers can opt to purchase tanks or have them supplied. INOXPA will supply the drawings should a customer purchase the tanks

- Customers can fit the pipes and connections between the tanks and the base frame or receive pre-connected equipment INOXPA will supply the pipe and connection schemes should a customer carry out the work

- 4 different models (10, 15, 20, and 25 m³/h)

- The possibility of 1 or 2 lines for each model

- The base frame includes the following elements:

- HCP pump(s),

- Tubular exchanger(s),

- Single seat multiway valves with a C-TOP+ control unit,

- Steam control valve(s),

- Return filter(s),

- Temperature probe(s) at the pump outlet,

- Electromagnetic flow meter(s),

- Conductivity meter(s) in the return line/s,

- Flow detector(s) in the return line/s,

- Stainless steel electric panel with Siemens PLC (S/7),

- a 9”/12” touchscreen, and variable-frequency drive(s) for pump(s)

Materials

- Tanks for chemical product: AISI 316L

- Tanks for water: AISI 304

- Tank insulation: Mineral wool

- Piping and components in contact with the product: AISI 316

- Other parts: AISI 304

- Gaskets in contact with the product: EPDM

Options

- Pressure gauge(s) in the impulsion line(s)

- Disinfection cycle, through in-line product dosing

- Recirculation in the product tank using the Estampinox pump and conductivity control

- CIP return pump(s)

- Allen-Bradley Compact Logix PLC and Rockwell display

- Communication systems between the CIP and other plant panels

- Operating parameters record

Related products

- Processing System

INOXPA MBC Double Cone Blender

- Processing System

INOXPA HTST Pasteuriser

- Processing System

INOXPA CIP PH Skid Mounted Units