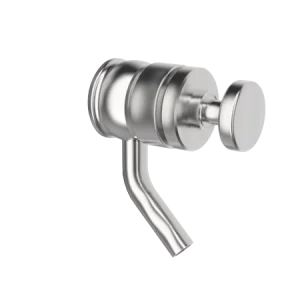

SERVINOX SHP Valve

Description

Specification

Description

The valves in the SHP range are PED certified security equipment intended to protect production lines and tanks containing group 2 gaseous fluids against excess pressures (service pressure above 0.5 bar). The pressurised blow-off is collected. SERVINOX possesses tools to dimension a valve with respect to tank or transfer line characteristics (diameter, height) and service conditions. Tank and process equipment demanding the highest standards in hygiene (agrifood, pharmaceuticals, cosmetics) Tanks subject to PED compliance where the service pressure is more than 0.5 bar Designed to transport groups 1 & 2 gases and water vapour (in line with component compatibility with the products)

Specification

Specification

- High performance safety valve: KD gas and vapour 0.74

- Flush hygienic design on tank dome with RA less than 0.6 μm

- Fully autonomous (no external control required for its operation)

- Compliant with «ATEX 2014/68/CE zones 1 & 2, gas and dust»

Materials

- Body, seat and non-return valve: 1.4404 (316L) or 1.4409 stainless steel

- Sealing: EPDM (Ethylene-Propylene-Diene Monomer) and NBR (Nitrile rubber) gaskets (max 120 °C)

- Materials not in contact with the product: 1.4306 or 1.4307 (304L) or 1.4404 (316L) stain

- Permitted fluids: Groups 1 & 2 vapours and gases

Options

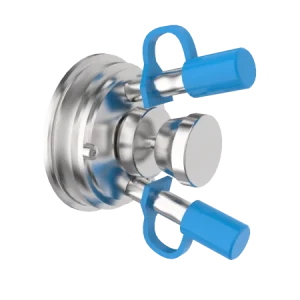

- Manual forced opening; automatic (from DN20)

- Pressurised inductive opening detection

- Other gaskets (specific service conditions): FKM (Fluorocarbon rubber, eq. Viton®), FFKM (Perfluoroelastomer, eq. Kalrez®), VMQ (Silicone), HNBR (Hydrogenated Nitrile rubber), NBR (Nitrile rubber),

- Gaskets USP Class VI compliant

- * ØE and ØF: other connection dimensions possible (please contact us)

Related products

- Other Valves

SERVINOX PEMA Valve

- Other Valves

SERVINOX PEMS Valve

- Other Valves

SERVINOX BOT Valve