MBS PHARMAFLO

Description

Specification

Description

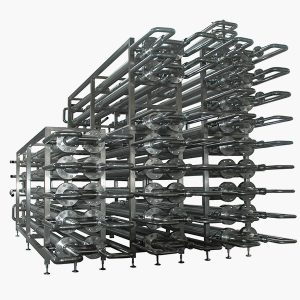

PHARMAFLO Heat Exchanger is realized to meet the pharmaceutical industry need/request of high hygienic measures. PHARMAFLO Heat Exchanger is manufactured by small diameter corrugated tubes inside an external jacket with tube plate on both ends. This solution remove the possibility of any contamination between sterile product and service fluid. An expansion joint is fitted on external jacket. The product to be thermally processed flows inside the small diameter tubes while service fluid flows inside the external jacket Application range Particularly suited for thermal exchange process of pharmaceutical fluids having a low or medium viscosity as for example WFI point of use cooling – WFI heating – condensation.

Specification

Specification

- Forged block made of Duplex, SAF2205, 3 Plungers made of AISI630L

- Direct transmission system with trapezoidal belts and pulleys

- Homogenizing group with hydro-pneumatic adjustment of the pressure for a great stability and homogenizing valvesin stellite™

- Flat valve seat and poppet/ball valves type made of stellite 20™

- Digital pressure transmitter, 4-20 mA, with ceramic membrane

- Overpressure valve, flow switch alarm

- Splash lubrication system, die cast alluminium crankcase, nitrurized crankshaft

- Terminal box and control panel for local/remote control

- Easy opening panels

Materials

- Parts in contact with the media: St.St.S 316L

- Single mechanical seal (dry running)

- Sterile sampling system

Options

- Second stage homogenizing group

- Vibration and temperature monitoring and alarm

- Forged multi-block made of Super Duplex, SAF2507

- Soundproof design

- Aseptic execution

- Sterile water generator by means of condensed steam generator

- Patent pending sterile water generator by means of microfiltration

- Electric power board for fixed or variable capacity

- Remote control by 4-20 mA signal

- Fully automatic pressure control by means of PLC

- Design suitable with 3A, EHEDG, or PHARMA standards

- Low roughness and electropolished wetted parts

- Certification manual for cGMP

- Standard or Sharp Edge Homogenizing valve with different geometries

- Materials availability: Tungsten carbide, Zirconia Oxide

- Explosion proof design

- Seat valve made of Tungsten carbide

Related products

- Heat Exchanger

MBS Sanitary MIXFLO Multitube Demontable

- Heat Exchanger

MBS Sanitary MIXFLO Anular Space Series

- Heat Exchanger

MBS Sanitary MIXFLO Multitube