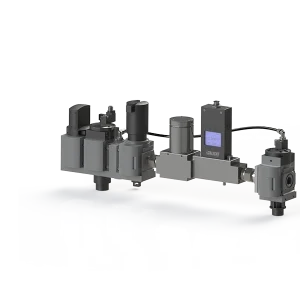

INOXPA STERIPIG

The PIG system is ideal for the recovery of any product remaining in a pipeline in the end of the transfer process. As this product can be of a high value the PIG system recovers the product removing it from the pipelines and preparing the pipeline for a CIP process. Another benefit is the reduction of the fluid sent to the sewage treatment plant that results in saving energy and water.

The PIG system is ideal for the recovery of any product remaining in a pipeline in the end of the transfer process. As this product can be of a high value the PIG system recovers the product removing it from the pipelines and preparing the pipeline for a CIP process. Another benefit is the reduction of the fluid sent to the sewage treatment plant that results in saving energy and water. The main application of the system is viscous media. Among the products treated there are chocolates, marmelades, confectionary creams in the food-processing industry, or gels, creames and other body care products of high value in the cosmetic industry.

Design & Features

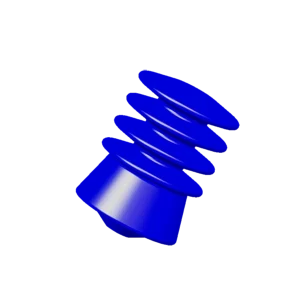

- PIG can pass through 1.5D bends.

- Size ranges: From 1 ½” (DN 40) to 3″ (DN 80).

- Hygienic design according to the EHEDG specifications

Materials

- Metal parts in contact with the product: AISI 316L

- Other metal parts: AISI 304

- PIG: Silicone

- Gasket (standard): EPDM according to FDA 177.2600

Option

- Connections: DIN, RJT, SMS, etc.

- Spheres: EPDM and Viton ®.

- Gaskets: Silicone, PTFE, Viton ®.

- Various levels of automation.

- Control panel.

Related products

- Pigging System

INOXPA SILPIG

- Pigging System

SERVINOX RVO

- Pigging System

SERVINOX Pigging System XSR