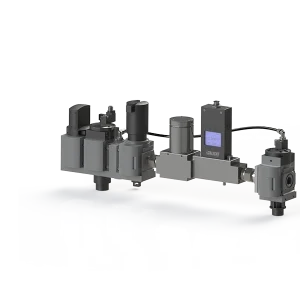

SERVINOX Pigging System XSR

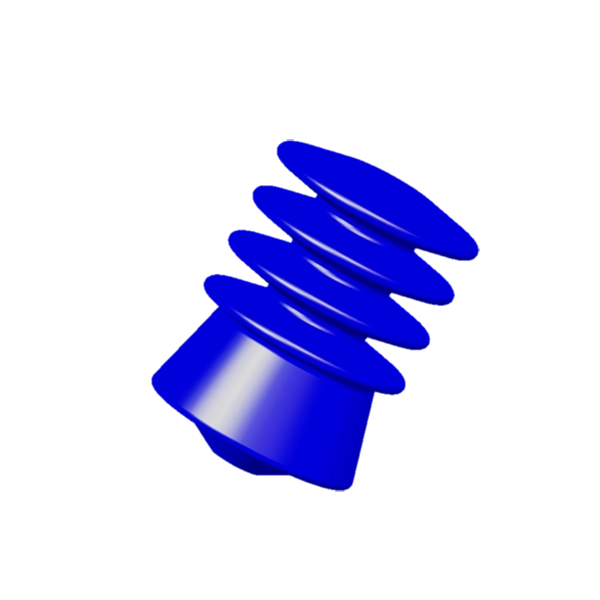

Servinox pigging system is intended to recover the residual mass in the piping using a pig. The pig is posi-tioned upstream of the zone to be evacuated, then sent in the piping by a thrus-ting fluid (gas or liquid).

Description

Specification

Description

Servinox pigging system is intended to recover the residual mass in the piping using a pig. The pig is posi-tioned upstream of the zone to be evacuated, then sent in the piping by a thrus-ting fluid (gas or liquid).

Pigging on transfer lines for all types of liquids

This equipment is particularly suitable for lines dispensing viscous, laden and/or solidifying liquids (creams, chocolate, caramel, paints, lubricants, etc.)

Specification

Design & Features

- Reduced product losses (recovery greater than 99.5 %)

- Pigging of all products conveyed in a pipe (viscous, laden, solidifying, etc.)

- Greater flexibility in the use of lines by reducing the risk of cross-contamination

- Elimination of the dilution phenomenon induced by water pushing without a pig

- Reduction in the volume of effluent to be treated

- Reduced consumption of cleaning agents and washing cycles

- Reduced operating costs and return on investment from the first year of use

- Tailor-made system to suit all requirements and constraints

- Modularity and possibility of having several supplies and several product distributions on the same line

Materials

- Parts in contact with the product: Stainless steel 1.4404 (316L)

- Other parts: Stainless steel 1.4301 (304L)

- Sealing: EPDM, FKM, Silicone, NBR depending on compatibility

Option

- Pigging use security in automatic condition

- Launching station heating element (jacketed piping)

- Station orientation: horizontal or vertical

- CIP connection/power tap on station

- Process fluid launching station isolation: see sheet ref. MV

- Pig speed control unit: see sheet RVO

- Intermediary station or distribution valve

- Surface state less than 0.8 µm

- Compliant with «ATEX 2014/34/UE zones 1 & 2, gas and dust» on request

- Other gaskets: VMQ (Silicone), FKM (Fluorocarbon rubber, eq. Viton®) or NBR (Nitrile rubber)

- Other pig qualities: EPDM (Ethylene Propylene Diene Monomer), NBR, FKM, PTFE filled VMQ, special mixes on request

Related products

- Pigging System

INOXPA STERIPIG

- Pigging System

INOXPA SILPIG

- Pigging System

SERVINOX RVO